Plastics : Blow Molding and Thermoforming processes Simply explained

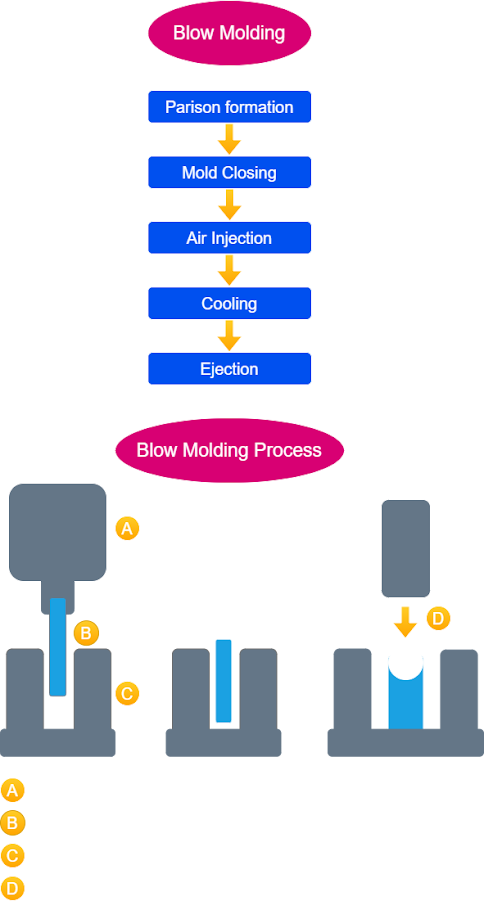

Parison Formation:

- Tube extrusion

- Wall thickness

- Length control

Mold Closing:

- Parison capture

- Pinch-off

- Seal formation

Air Injection:

- Pressure control

- Expansion

- Shape forming

Cooling:

- Wall setting

- Temperature control

- Time management

Ejection:

Main role of blow molding:

- Creates hollow plastic items

- Makes containers and bottles

- Works like blowing up a balloon inside a mold

Best Used For:

Containers:

- Water bottles

- Soda bottles

- Shampoo bottles

- Milk jugs

- Chemical containers

Large Items:

- Fuel tanks

- Storage drums

- Industrial containers

- Large water tanks

Characteristics:

- Hollow inside

- Even wall thickness

- Strong construction

- Good for liquids

Process Benefits:

- Production:

- Fast production

- Consistent quality

- High volume possible

- Cost-effective

Design:

- Complex shapes possible

- Built-in handles

- Various sizes

- Good strength

Remark:

A parison is a hollow, tube-shaped piece of molten plastic that's extruded before blow molding.

Think of it like a hot plastic tube that will become a bottle or container.

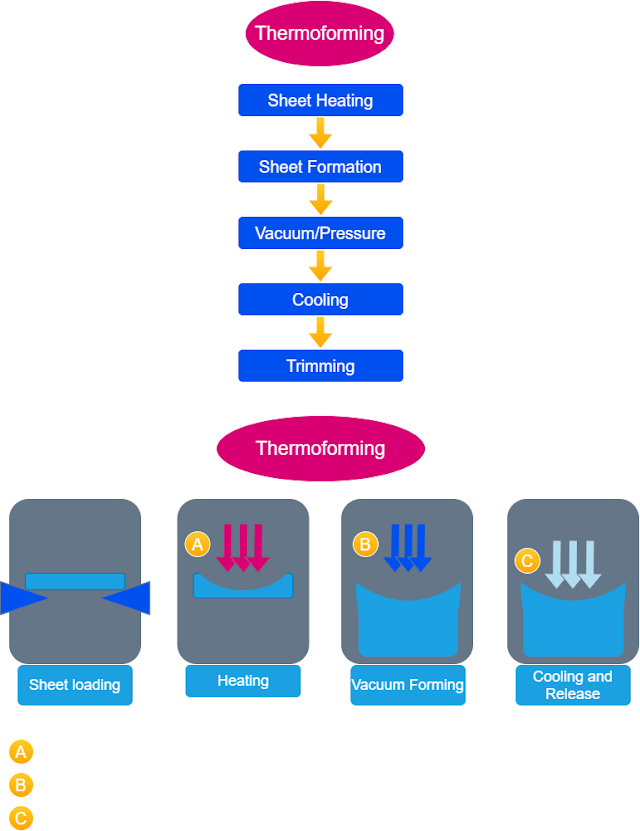

Thermoforming process:

The below describes the elements in the above diagram:

Sheet Heating:

Sheet Heating:

- Temperature control

- Heat distribution

- Sag control

Sheet Formation:

- Mold contact

- Pre-stretch

- Material distribution

Vacuum/Pressure:

- Shape forming

- Detail reproduction

- Wall thickness

- Shape setting

- Temperature control

- Cycle time

Trimming:

- Edge removal

- Part separation

- Scrap handling

Main Role:

- Creates shaped plastic items from sheets

- Makes packaging and trays

- Works like vacuum-sealing plastic over a mold

Best Used For:

Packaging:

- Food containers

- Blister packs

- Electronics packaging

- Medical trays

- Product displays

Large Panels:

- Vehicle parts

- Refrigerator liners

- Shower units

- Signs

- Machine covers

Characteristics:

- One-sided detail

- Thin walls

- Large surface areas

- Uniform thickness

Process Benefits:

Production:

- Lower tooling costs

- Quick setup

- Large parts possible

- Good for small runs

Design:

- Fine detail possible

- Large surfaces

- Clear products

- Texture options

Quick Comparison:

Blow Molding:

- Makes : Hollow items

- Best for : Bottles and containers

- Strengths : Liquid containers

- Cost : Higher setup, lower per piece

Thermoforming:

- Makes : Shaped sheets

- Best for : Packaging and trays

- Strengths : Large, detailed surfaces

- Cost : Lower setup, higher per piece

Comments

Post a Comment